Heat is one of the most damaging forces that materials face in industrial and daily life settings. From the inner chambers of jet engines and power plants to kitchen cookware and automotive exhaust systems, extreme temperatures can weaken, deform, or destroy materials if left unprotected. One of the key innovations used to safeguard these materials is heat-resistant coatings.

These coatings act as a barrier between the base material and thermal stress, offering longevity, efficiency, and safety. But how exactly do they work? What scientific principles enable them to endure hundreds—or even thousands—of degrees Celsius without breaking down? In this article, we’ll deep-dive into the science behind heat-resistant coatings, covering the chemistry, physics, material science, and advanced applications that make them possible.

1. Why We Need Heat-Resistant Coatings

The Problem with Heat

Every material has a thermal limit—a temperature beyond which it loses its strength, oxidizes, or melts. For example:

- Steel starts to lose significant strength around 500°C.

- Aluminum melts at ~660°C.

- Plastics often soften below 200°C.

Industries working with combustion, furnaces, engines, or turbines routinely face temperatures ranging from 600°C to over 1,200°C. Without proper protection, metals and composites would deform, oxidize, corrode, or crack under thermal stress.

The Role of Heat-Resistant Coatings

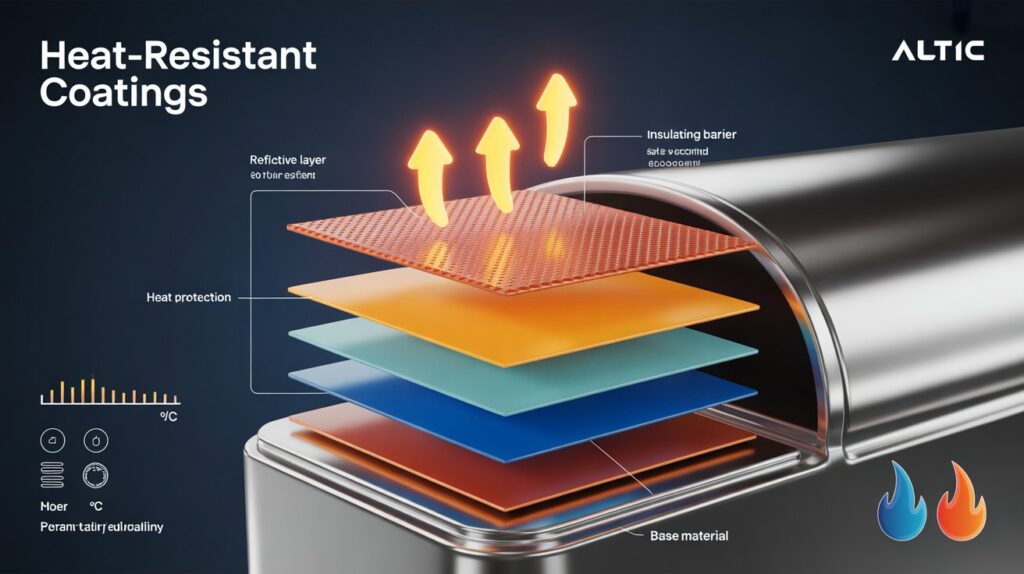

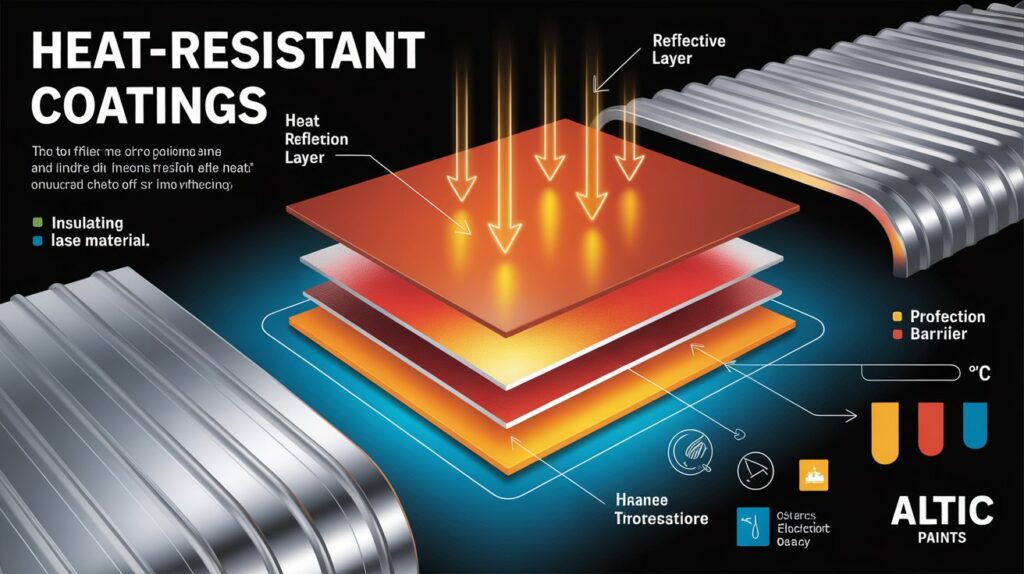

Heat-resistant coatings provide a protective thermal barrier that delays or prevents damage. Their roles include:

- Thermal insulation – reducing heat transfer to the substrate.

- Resistance to oxidation – preventing surface reactions with oxygen at high temps.

- Durability – maintaining adhesion and structure across thermal cycles.

- Safety & efficiency – keeping components intact and energy-efficient.

Simply put, these coatings are the unsung heroes that make modern high-heat technology possible.

2. The Science Fundamentals Behind Heat-Resistant Coatings

To understand how heat-resistant coatings work, we need to explore a blend of physics, materials science, and chemistry.

2.1 Thermal Conductivity and Insulation

The core principle is controlling heat flow. Materials with low thermal conductivity (like ceramics or polymers) slow down how fast heat passes through. Heat-resistant coatings use such materials as a shield, ensuring the underlying substrate remains cooler than the environment.

2.2 Thermal Expansion and Stress Resistance

When exposed to heat, most materials expand. If the coating and the substrate expand at different rates, stresses build up, leading to cracks or delamination. Engineers therefore carefully select coatings with compatible coefficients of thermal expansion (CTE) to minimize stress.

2.3 Chemical Stability at High Temperatures

Many coatings use oxides, carbides, or nitrides because they remain chemically stable at extreme temperatures. Unlike metals that oxidize, these compounds can withstand high-temp chemical reactions without breaking down.

2.4 Radiation and Reflectivity

Instead of absorbing radiant heat, certain coatings provide protection by reflecting it. Coatings that are bright and reflective, such as aluminum silicates or specialty ceramics, can divert infrared light from the substrate.

Together, these scientific properties explain how coatings resist extreme environments.

3. Types of Heat-Resistant Coatings and Their Mechanisms

Heat-resistant coatings come in a wide variety, depending on what they are meant to protect and under what conditions. Let’s explore the most common types:

3.1 Ceramic-Based Coatings (Thermal Barrier Coatings – TBCs)

Ceramics are great thermal insulators because they are poor heat conductors. Ceramic coatings significantly limit heat transmission when applied in thin layers.

- Common materials: Zirconia (ZrO₂), Alumina (Al₂O₃), and Mullite.

- Applications: Gas turbines, aerospace engines, rocket nozzles.

- Mechanism: They create a highly porous microstructure that traps air (an excellent insulator). For applications requiring high temperatures, zirconia—in particular, yttria-stabilized zirconia (YSZ)—is the preferred material.

3.2 Metallic Heat-Resistant Coatings

Metals are conductive, yet certain alloys are engineered for resistance to oxidation and heat fatigue.

- Chromium, Aluminum, and Nickel-based alloys are often used.

- They form a protective oxide layer (self-passivation) that shields against further damage.

- Common in industrial furnaces, petrochemical plants, exhaust systems.

3.3 Polymer and Silicone-Based Coatings

For moderate heat levels (200–600°C), heat-resistant polymers are highly useful.

- Silicone-based paints withstand continuous heat exposure and provide oxidation resistance.

- Used in cookware, automotive headers, grills, and chimneys.

3.4 Powder Coatings with Heat-Resistant Properties

Powders with high-temperature stability like epoxy, polyester, or acrylic formulations can be cured onto surfaces, creating a durable heat shield that resists flaking.

3.5 Intumescent Coatings

These coatings don’t just resist heat—they expand when exposed to fire, forming an insulating foam layer.

- Widely utilized in structural steel and fireproofing buildings.

- Mechanism: Special compounds undergo a chemical reaction upon heating, swelling into a porous carbonaceous char that delays heat transfer.

4. How Heat-Resistant Coatings Are Engineered

4.1 Microstructural Design

The performance largely depends on microstructure:

- Porous microstructures trap air and lower conductivity.

- Multilayered architecture alternates between metallic bond coats and ceramic topcoats for durability.

4.2 Deposition Methods

4.3 Adhesion Science

For coatings to function, they must stay in place despite heat cycles. Adhesion promoters, intermediate bond coats, or roughened substrates are often used to lock coatings in firmly.

5. Challenges with Heat-Resistant Coatings

Despite their benefits, these coatings face several scientific and engineering challenges:

- Thermal Fatigue: Repeated heating and cooling (thermal cycling) can cause cracks.

- Spallation: Coatings peeling or flaking off under stress.

- Chemical Degradation: Interaction with corrosive environments (salt, combustion gases).

- Cost and Scalability: High-tech coatings like yttria-stabilized zirconia are expensive.

Researchers continuously innovate to overcome these challenges using nanotechnology, advanced composites, and hybrid coatings.

6. Latest Advances and Innovations

6.1 Nanostructured Heat-Resistant Coatings

At the nanoscale, coatings can be engineered with unique features:

- Enhanced resistance to crack propagation.

- Better adhesion and flexibility.

- Optimized heat reflectivity.

6.2 Self-Healing Coatings

Some experimental coatings integrate compounds that re-seal cracks automatically when exposed to oxygen or heat, reducing maintenance needs.

6.3 Environmental Sustainability

Eco-friendly, low-VOC (volatile organic compound) formulations are emerging to replace solvent-heavy coatings, balancing environmental responsibility with performance.

6.4 Extreme Applications (Space & Aerospace)

Aerospace research is pushing limits with coatings that handle re-entry temperatures above 1600°C, paving the way for spacecraft, hypersonic jets, and reusable space vehicles.

7. Real-World Applications

Heat-resistant coatings with varied formulations can be found across industries:

- Aerospace & Aviation – thermal barrier coatings for jet engines, rockets, and turbine blades.

- Automotive – exhaust systems, turbochargers, brake components.

- Construction & Infrastructure – fireproof intumescent coatings for steel structures.

- Industrial Manufacturing – furnaces, chimneys, refinery systems.

- Consumer Goods – cookware, grills, stovetops, and home heating appliances.

- Energy Sector – gas turbines, boilers, nuclear plants.

Without heat-resistant coatings, many of these industries simply wouldn’t function at the scale we take for granted.

8. Future Outlook

The demand for next-generation heat-resistant coatings is on the rise, with industries moving toward cleaner energy, electrification, and space travel. Some trends shaping the future include:

- Smarter coatings that can sense and report damage.

- Materials that combine metals, polymers, and ceramics to provide multifunctional protection.

- 3D-printing of coatings for tailored microstructures.

- Affordable high-tech coatings that enable mass adoption beyond aerospace and defense.

Conclusion

Although heat is a creative and destructive force, it also destroys exposed materials and fuels motors, industrial manufacturing, and modern conveniences. Heat-resistant coatings act as armor, shielding metals, composites, and structures from thermal degradation.

They leverage principles of thermal insulation, chemical stability, tailored microstructures, and advanced deposition techniques to remain stable where ordinary materials fail. From silica-based reflective paints in household grills to nanostructured ceramics in rocket engines, these coatings are everywhere, though often unnoticed.

As research pushes the boundaries of chemistry and materials science, heat-resistant coatings will only become more advanced, enabling technologies like hypersonic travel, safer infrastructure, and longer-lasting consumer goods.

The science behind them reveals more than just surface protection—it shows how human ingenuity can control one of nature’s most destructive forces.