Understanding Corrosion: The Enemy Altic Paint Is Designed to Fight

To understand why Altic Anti-Corrosive Paint is so effective, it is important to first understand the science of corrosion itself.

1.1 The Electrochemical Reaction

Corrosion is essentially a natural electrochemical reaction where metal reacts with oxygen and moisture, forming oxides—commonly known as rust.

When metal is exposed to:

- Air

- Water

- Salts

- Acids

- Pollutants

- Chemical vapors

…it begins to oxidize. This oxidation weakens the material from the surface inward.

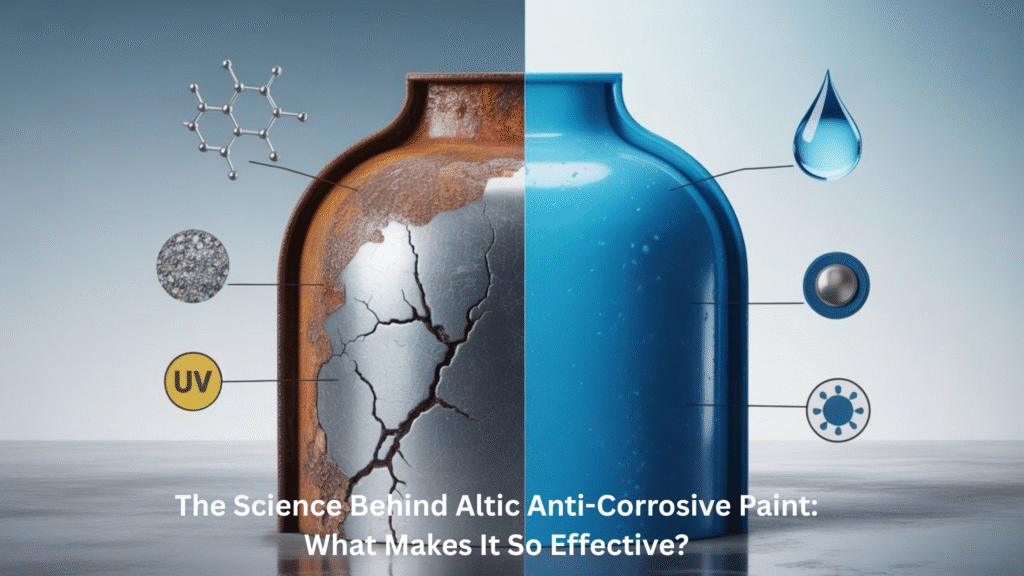

1.2 Why Regular Paint Fails

Most ordinary paints only provide a superficial layer of protection. They cannot:

- Stop moisture from penetrating

- Prevent oxygen from reaching the metal

- Withstand industrial or marine exposure

- Resist chemical splashes

- Handle thermal expansion or contraction

As soon as this layer cracks, peels, or wears down, corrosion begins underneath.

1.3 The Cost of Corrosion

Globally, corrosion costs industries more than a trillion annually, according to NACE International.

This includes:

- Structural failures

- Shutdown time

- Repairs and repainting

- Replacement of equipment

- Preventive treatment

This makes anti-corrosive coatings not a luxury but a necessity in modern operations.

The Science Inside Altic Anti-Corrosive Paint

Altic’s formulation is the biggest reason for its effectiveness. The paint uses advanced barrier technology, corrosion inhibitors, adhesion boosters, and special polymers that actively protect the substrate.

Let’s break down the science:

2.1 Barrier Protection: Stopping Corrosion Before It Starts

The first and most important defence mechanism is the paint’s ability to form a dense protective barrier.

Altic Anti-Corrosive Paint contains:

- High-performance resins

- Reinforced pigment particles

- Micro-fine fillers

Together, they create a compact, tightly packed film, blocking:

- Oxygen

- Water molecules

- Salts

- Industrial pollutants

- UV exposure

This barrier prevents metal surfaces from coming into contact with elements that trigger corrosion.

How It Works Scientifically

Water molecules are small and can penetrate weak or porous coatings easily.

Altic ensures that the paint’s molecular structure is arranged in a high-density matrix, making penetration extremely difficult.

This is known as passive protection, and it’s essential for long-term durability.

2.2 Anti Corrosion Inhibitors: Neutralizing Rust at the Chemical Level

Unlike regular paints, Altic contains active corrosion inhibitors.

These compounds react with the metal surface or environment to neutralize corrosive ions like chlorides and sulfates.

Types of Inhibitors Used

Though specific formulas vary by product, they may include:

- Zinc-rich compounds (for galvanic protection)

- Phosphate-based inhibitors

- Chromate alternatives (eco-friendly)

- Organic corrosion-blocking molecules

These inhibitors form a microscopic protective layer directly on the metal surface, disrupting corrosion chemistry.

Why This Is a Game-Changer

Even if the coating develops micro-cracks or is slightly damaged, inhibitors inside the paint migrate to the exposed area and minimize rusting.

This is known as active protection, and only advanced coatings offer this feature.

2.3 Superior Adhesion Technology for Long-Term Performance

Another critical factor is adhesion.

Good adhesion ensures that the coating remains intact during:

- Mechanical impact

- Temperature changes

- Vibrations

- Expansion and contraction

- Abrasion

- Chemical exposure

Altic Anti-Corrosive Paint uses adhesion promoters that chemically bond the coating to the metal substrate.

This prevents:

- Peeling

- Flaking

- Delamination

- Under-film corrosion

Higher adhesion means better resistance and a longer lifespan.

2.4 Hydrophobic Polymers for Water Resistance

Water is the biggest catalyst for corrosion.

Altic incorporates hydrophobic polymers that repel moisture at the molecular level.

How Hydrophobicity Works

The paint’s surface develops a low-energy film, making it difficult for water molecules to cling to it.

Hydrophobic technology ensures:

- Faster drying

- Non-wetting behavior

- Less moisture absorption

- Reduced risk of blistering

This significantly improves the coating’s ability to perform in humid, rainy, or marine environments.

2.5 UV and Chemical Resistance for Harsh Environments

UV rays and industrial chemicals can cause ordinary paints to:

- Fade

- Crack

- Oxidize

- Lose adhesion

Altic Anti-Corrosive Paint contains UV-stabilizing additives and anti-oxidation compounds that maintain the coating’s structural integrity under severe exposure.

In industries such as:

- Petrochemical

- Manufacturing

- Marine

- Power plants

- Warehousing

- Steel fabrication

…these qualities are essential for ensuring reliable, long-lasting protection.

The Multi-Layer Protection System: Why Altic Outperforms Ordinary Coatings

Altic Anti-Corrosive Paint doesn’t rely on just one mechanism.

Instead, its performance comes from a three-tier protection system:

3.1 Physical Barrier

A dense polymer film blocks external elements.

3.2 Chemical Shield

Corrosion inhibitors actively neutralize rust-causing ions.

3.3 Mechanical Durability

High adhesion and flexibility protect against physical wear.

This multi-pronged approach ensures superior protection in both indoor and outdoor environments.

Real-World Applications: Where Altic Anti-Corrosive Paint Excels

Due to its formulation and performance, Altic is used across diverse industries.

4.1 Industrial Structures

- Factories

- Steel beams

- Machinery

- Storage tanks

4.2 Marine & Offshore

- Ships

- Docks

- Marine equipment

- Coastal structures

Marine environments are highly corrosive because of saltwater exposure.

Altic’s hydrophobic and inhibitor-rich formula is ideal here.

4.3 Oil & Gas

- Pipelines

- Refineries

- Processing units

These settings require coatings that withstand chemicals and high temperatures.

4.4 Automotive & Transport

- Vehicles

- Trailers

- Shipping containers

Corrosion can compromise safety and load-bearing capacity.

4.5 Construction & Infrastructure

- Bridges

- Railings

- Metal roofing

- Structural sections

Long-term exposure to rain, sun, and pollution makes durable coatings vital.

Performance Testing: What Proves Altic’s Effectiveness?

Altic Anti-Corrosive Paint undergoes rigorous testing protocols, including:

5.1 Salt Spray Test (ASTM B117)

Simulates marine and high-salt conditions.

5.2 Adhesion Test (ASTM D3359)

Checks coating bond strength.

5.3 Water Immersion Test

Ensures no blistering or surface degradation.

5.4 Accelerated Weathering (UV)

Measures resistance to sunlight and oxidation.

5.5 Chemical Resistance Test

Evaluates durability in harsh industrial atmospheres.

These tests prove that Altic performs consistently across varied environmental conditions.

Application Techniques: Unlocking Maximum Performance

Even the best paint requires proper application for optimal results.

6.1 Surface Preparation

- Remove rust

- Clean contaminants

- Abrade the surface

- Ensure dryness

6.2 Application Methods

- Brush

- Roller

- Spray (airless, air-assisted)

Altic is designed to provide excellent coverage with minimal effort.

6.3 Recommended Coating Thickness

The ideal thickness ensures long-lasting protection without overuse.

6.4 Curing Time

Proper curing strengthens the molecular bonds and maximizes corrosion resistance.

Environmental Benefits: A Coating for the Future

Modern industries prioritize sustainability.

Altic Anti-Corrosive Paint is engineered with:

- Low-VOC formulations

- Eco-friendly corrosion inhibitors

- Reduced solvent emissions

- Long-lasting durability (fewer repaints)

By extending equipment life and reducing frequent repainting cycles, it cuts down on waste and resource consumption.

Why Altic Anti-Corrosive Paint Is Trending in 2025

Across B2B markets, maintenance teams, and engineering forums, Altic is receiving significant attention. Here’s why:

8.1 High ROI for Industries

Reduces repair and replacement costs.

8.2 Reliable Protection in Extreme Conditions

From coastal climates to chemical plants.

8.3 Strong Market Reputation

Industries trust performance-based results.

8.4 Advanced Formulation

Backed by scientific research and testing.

8.5 Growing Demand for Durable Coatings

Modern infrastructure increasingly requires long-lasting protection solutions.

Final Thoughts: The Science That Sets Altic Apart

Corrosion is inevitable, but damage isn’t.

Altic Anti-Corrosive Paint uses advanced chemistry and multi-layer protection technology to deliver one of the strongest and most reliable shields against rust. Its combination of:

- Barrier protection

- Active inhibitors

- Strong adhesion

- Hydrophobic polymers

- UV resistance

- Chemical durability

…makes it exceptionally effective across industries.

As infrastructure investments rise and industries seek more durable, cost-effective, and eco-friendly solutions, Altic Anti-Corrosive Paint stands out as a coating built for the future.

Its foundation is simple: science-backed performance that saves time, money, and assets—year after year.

Pingback: Different Types of Anti-Corrosive Paint & Their Uses