Introduction

Fire incidents in electrical systems pose some of the most serious risks to industries, data centers, and infrastructure. Once fire spreads through cables, it can compromise escape routes, disable critical power supply systems, and cause irreparable damage. ALTIC 0120 Fire Stop Coating is specifically designed to address this challenge. It is a water-based, intumescent fire retardant paint that provides flexible, durable, and reliable fire protection for cables, trays, and penetrations. Tested and certified by National Test House (NTH), Mumbai, ALTIC 0120 ensures circuit integrity for up to 4 hours, giving valuable time for evacuation and firefighting.

Key Features and Advantages

- Certified Fire Protection: Tested and certified at NTH Mumbai for 4-hour circuit integrity.

- Intumescent Action: Expands up to 10 times when exposed to fire, forming an insulating char.

- Thin, Flexible Film: Approx. 500 microns thickness offers protection without affecting cable performance.

- Halogen & Asbestos Free: Eliminates release of toxic halogen gases during fire.

- No Cable Rating Reduction: Unlike heavy wraps, ALTIC 0120 preserves the original current carrying capacity.

- Extended Escape Time: Maintains power supply longer during fire, ensuring safer evacuation.

- Reduced Smoke & Drips: Controls smoke emission and minimizes falling burning fragments.

- UV, Water, Oil & Chemical Resistance: Withstands outdoor exposure and industrial environments.

- Eco-Friendly: Water-based, non-toxic, low VOC (<100 gm/kg).

- Long-lasting Performance: Can be top-coated with epoxy varnish for extended service life.

Certifications and Standards

- NTH Mumbai Certification – 4 hours of fire protection for cables.

- NFPA 703 Compliant – Fire retardant for wood and building materials.

- ASTM Standards:

- ASTM E-162: Flame Spread Test

- ASTM E-662: Smoke Generation Test

- ASTM E-84: Surface Burning Test

- ASTM D-1360: Cabinet Method Fire Retardancy Test

Technical Specifications

- Type: Water-based, intumescent, fire-retardant, flexible thin film coating

- Color: Off-white (custom shades available)

- Finish: Matte

- Curing Time: Surface dry – 60 min; Track free – 8 hrs; Hard dry – 48 hrs

- Non-volatile Matter: Min 70%

- Scratch Hardness: No exposure of bare surface

- Flexibility & Adhesion: Excellent; no cracking or detachment after 48 hrs

- Resistance: Water, oil, mild acid & alkali resistant

- Shelf Life: 1 year (in sealed container, cool dry place)

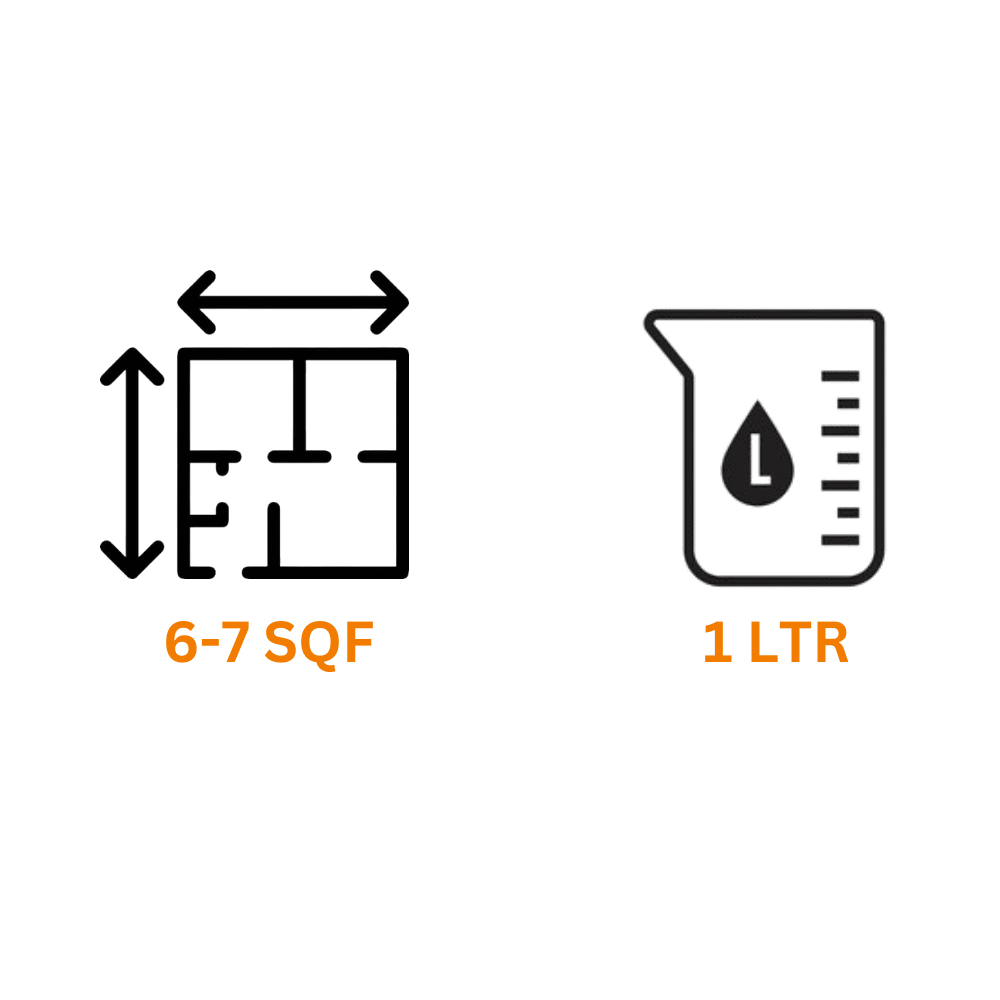

- Coverage (per kg):

- 30 min – 24–25 sq.ft. @ 500 microns

- 1 hr – 10–12 sq.ft. @ 1000 microns

- 2 hr – 5–6 sq.ft. @ 2000 microns

- 3 hr – 4 sq.ft. @ 3000 microns

- 4 hr – 2.5–3 sq.ft. @ 4000 microns

Applications

- Cable coatings in power plants, data centers, and industrial facilities

- Cable penetration seals in walls and floors

- Cable trays in control rooms and substations

- Flammable substrates like wood for added fire safety

- High-risk environments requiring extended fire protection

Application Procedure

- Surface Preparation: Clean, dry, and dust-free surface. Temperature above 20°C.

- Mixing: Stir well before use; adjust viscosity with soft water if required.

- Application: Apply by brush or airless spray. Use minimum 2 coats to achieve 500 microns DFT.

- Topcoat (optional): Apply Ugam Epoxy Topcoat for decorative finish or long-term outdoor use.

- Metallic Surfaces: Use ALTIC Zinc Rich Primer before application.

Storage & Shelf Life

- Supplied in 20 kg buckets

- Shelf life: 1 year under cool, dry storage conditions

- Avoid freezing and direct sunlight

Case Studies & Projects

ALTIC 0120 has been successfully applied across India for leading industrial and infrastructure clients:

- Mylan Laboratories (PAN India)

- Schneider Electric

- Pidilite Industries

- ONGC Ltd

- Ozone Spinter Ltd

- HCL Technologies

- Ravi Export Ltd

- Indian Army – J&K

- Johnson & Johnson

Safety Precautions

- Use in well-ventilated areas.

- Avoid inhalation of mist; wear masks and gloves.

- In case of contact, wash with water and soap.

- Refer to MSDS for detailed safety guidelines.

Conclusion

ALTIC 007 Fire Stop Coating is an advanced intumescent fire retardant paint engineered for electrical cables, trays, and penetrations. It combines certified performance (NTH Mumbai, ASTM, NFPA compliance) with eco-friendly, halogen-free, and durable protection. By delaying flame spread, reducing smoke, and maintaining circuit integrity for up to 4 hours, ALTIC 0120 is a critical safety solution for industries, IT facilities, and infrastructure.

When it comes to fire safety in electrical systems—precaution is better than cure, and ALTIC 0120 ensures maximum protection where no cure is possible once fire starts.

Reviews

There are no reviews yet.