Surfaces and structures exposed to high heat need more than just regular paint. From industrial furnaces and pipelines to your home fireplace, extreme temperatures can cause normal coatings to blister, crack, and peel. This leads to expensive repairs, safety hazards, and reduced efficiency.

This is where heat resistant paint steps in. Also known as high-temperature paint or thermal protection coating, it is specially designed to withstand extreme heat without breaking down. It creates a protective barrier that not only resists high temperatures but also prevents corrosion, oxidation, and fire risks.

In this ultimate guide, we’ll explore what heat resistant paint is, how it works, its benefits, types, applications, and expert tips for choosing and applying it. By the end, you’ll know exactly how to protect your surfaces and equipment while saving money in the long run.

What is Heat Resistant Paint and How Does It Work?

Heat resistant paint is a specialized protective coating formulated with advanced resins, binders, and additives that can withstand continuous exposure to high temperatures—ranging from 200°C (392°F) to over 1200°C (2192°F). Unlike conventional paints that degrade when exposed to heat, this paint maintains its adhesion, finish, and protective qualities.

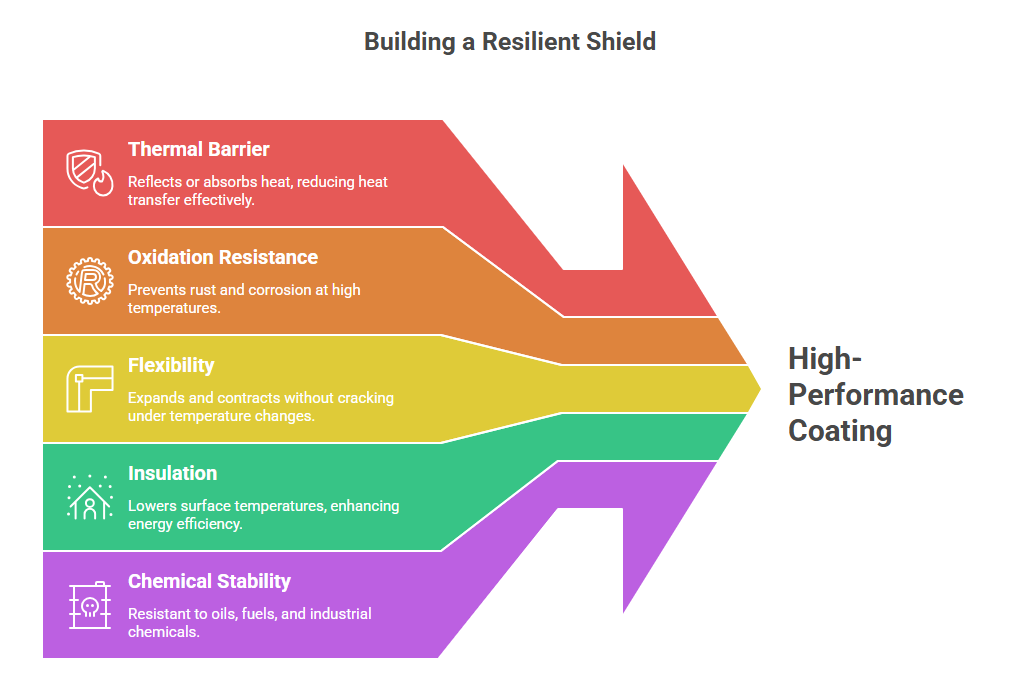

Key Working Principles:

For example, an automotive exhaust coated with high-temperature paint won’t rust or peel, even after continuous cycles of heating and cooling.

Key Benefits of Using Heat Resistant Paint

Investing in heat resistant paint brings multiple advantages that go beyond temperature resistance.

- Durability Under Extreme Heat – Stays intact and functional at high temperatures.

- Corrosion Prevention – Protects metals from rust and oxidation.

- Fire & Burn Protection – Reduces the risk of fire hazards in industrial and residential setups.

- Energy Efficiency – Lowers heat transfer, reducing cooling costs in factories, warehouses, and homes.

- Cost Savings – Extends the lifespan of equipment and reduces maintenance needs.

- Aesthetic Appeal – Available in multiple colours and finishes (black, silver, aluminium, matte, or glossy).

- Safety Compliance – Meets fire safety standards in industries and construction.

- Low Maintenance – Requires less frequent recoating compared to standard paints.

- Multi-Surface Compatibility – Works on steel, aluminium, concrete, and composites.

- Value Addition – Increases property and equipment value by offering long-term protection.

Common Applications of Heat Resistant Paint

Heat resistant coatings are versatile and widely used across industries and households.

1. Industrial Uses

- Boilers, furnaces, and heat exchangers

- Pipelines and chimneys

- Power plants and turbines

- Oil refineries and chemical plants

2. Automotive Applications

- Exhaust systems

- Engine blocks and manifolds

- Brake parts

- Motorcycle mufflers

3. Residential Applications

- Fireplaces and chimneys

- Kitchen ovens and stoves

- Barbecue grills

- Hot water tanks

4. Outdoor & Commercial Applications

- Outdoor furniture and heaters

- Structural steel in commercial buildings

- HVAC ducts and systems

- Bakery ovens and industrial kitchens

Whether it’s a massive power plant or your backyard BBQ grill, heat resistant paint ensures safety and long-term protection.

Types of Heat Resistant Paint: Which One is Right for You?

Not all heat resistant paints are the same. The right choice depends on the surface and the level of heat exposure.

- Silicone-Based Paints

- Withstand up to 600°C

- Weather-resistant and flexible

- Common in automotive exhausts and chimneys

- Epoxy-Based Heat Resistant Coatings

- Handle up to 200°C

- Great for pipelines, tanks, and industrial equipment

- Excellent chemical resistance

- Ceramic-Based Coatings

- Withstand extreme heat up to 1200°C

- Provide insulation and abrasion resistance

- Used in aerospace and power plants

- Intumescent Coatings

- Expand when exposed to heat, forming an insulating layer

- Fireproof structural steel in buildings

- Powder Coatings

- Withstand up to 500°C

- Durable, eco-friendly, corrosion-resistant

- Used on machinery, outdoor structures, and equipment

By identifying your needs, you can select the best option for your project.

Choosing the Right Heat Resistant Paint for Your Project

When selecting the right paint, consider these factors:

- Temperature Range: Match the paint’s rating with the maximum heat exposure of your surface.

- Surface Material: Metals, concrete, and composites may require different formulations.

- Environment: Indoor vs outdoor, chemical exposure, and moisture levels.

- Finish Options: Matte, glossy, or metallic finishes based on aesthetic preferences.

- Compliance: Check for ISO, ASTM, or other safety certifications.

- Brand Reliability: Choose trusted manufacturers like ALTIC, known for industrial-grade coatings.

For instance, if you’re painting an industrial chimney, a ceramic-based coating is more suitable than an epoxy paint designed for mild heat.

Step-by-Step Guide to Applying Heat Resistant Paint

Correct application ensures maximum performance. Here’s a simple guide:

1. Surface Preparation

- Clean thoroughly to remove rust, oil, and dirt.

- Sandblast or wire-brush for rough surfaces.

- Apply a compatible primer if required.

2. Application Methods

- Spray: Provides an even, smooth finish for large surfaces.

- Brush/Roller: Ideal for smaller projects or touch-ups.

- Dip Coating: Used for industrial batch applications.

3. Coating Process

- Apply thin, even layers for better adhesion.

- Follow manufacturer’s instructions for number of coats.

4. Curing

- Allow proper drying and curing under recommended temperature conditions.

- Some coatings require heat-curing to achieve full performance.

5. Inspection & Maintenance

- Check for uniform coverage.

- Recoat when signs of wear appear, though high-quality coatings last for years.

Real-Life Case Studies & Examples

- Automotive Exhaust Systems: Cars and bikes using heat resistant coatings show improved durability and reduced rust.

- Residential Fireplaces: Heat resistant black paint enhances appearance while preventing damage.

- Industrial Chimneys: Coatings withstand constant exposure to gases and high temperatures.

- Outdoor BBQ Grills: Protects from both heat and weather, keeping them in top condition longer.

Latest Innovations in Heat Resistant Paint

The coating industry is evolving rapidly. Some exciting innovations include:

- Nano-Coatings: Ultra-thin but highly effective layers with superior heat resistance.

- Self-Healing Coatings: Minor scratches repair themselves, extending life.

- Low-VOC Formulations: Eco-friendly options for safer applications.

- Smart Paints: Coatings embedded with sensors to monitor temperature.

- Hybrid Coatings: Combine heat resistance with corrosion and UV protection.

These technologies are shaping the future of protective paints, especially in aerospace, automotive, and energy industries.

Conclusion: Why You Should Invest in Heat Resistant Paint

Heat resistant paint is not just a specialty product—it’s a necessity wherever heat exposure is a concern. From protecting industrial machinery to enhancing the life of your home fireplace, it offers unmatched durability, safety, and cost savings.

By choosing the right type, applying it correctly, and maintaining it well, you can ensure your surfaces stay safe, efficient, and visually appealing for years.

For reliable, high-performance coatings, ALTIC Heat Resistant Paint is trusted across industries. With ISO-certified quality, advanced formulations, and proven results in Indian climates, ALTIC helps protect your investments while reducing costs.

👉 Protect your surfaces. Save energy. Ensure safety. Choose heat resistant paint today.

Pingback: Is Heat-Resistant Paint Worth It? Experts Reveal the Truth