Introduction

Fire incidents remain one of the biggest threats to modern industrial and commercial structures. With rapid urbanization and dense infrastructure, the need for effective fire protection has never been more critical. Structural steel, widely used in buildings, factories, bridges, and warehouses, is valued for its strength, flexibility, and durability — yet it has one major weakness: its vulnerability to heat.

When exposed to extreme temperatures, steel begins to lose its structural integrity, compromising the entire framework of a building. Within minutes, a fire can cause deformation, leading to catastrophic collapse.

This is where fire retardant paint for steel comes into play — a revolutionary coating technology that acts as a thermal shield against fire. These paints don’t just delay damage; they preserve lives, property, and investments. Modern solutions, such as ALTIC Fire Retardant Coatings, are redefining the standards of fire safety, offering advanced, cost-effective protection without compromising aesthetics or performance.

Understanding the Vulnerability of Structural Steel

Steel has long been the backbone of industrial and architectural design. Its high strength-to-weight ratio, ease of fabrication, and adaptability make it a preferred material for constructing skyscrapers, warehouses, refineries, and bridges. However, despite its durability, steel is not immune to fire.

When temperatures rise during a fire, steel begins to lose its strength rapidly. At around 550°C, steel can lose nearly 50% of its load-bearing capacity, and by 1000°C, it can soften completely. This dramatic drop in strength means even well-designed structures can buckle or collapse under the stress of fire loads.

The danger isn’t in the flames themselves but in the thermal transfer to the metal, causing it to expand and deform. Without protective coatings, steel structures in factories, power plants, or high-rises are at significant risk.

Therefore, fire protection for structural steel is not just a compliance requirement; it’s a safety imperative. It ensures that critical infrastructure maintains its integrity long enough for occupants to evacuate and for emergency teams to respond — minimizing damage and saving lives.

What Is Fire Retardant Paint and How Does It Work?

Fire retardant paint, also known as intumescent coating, is a specialized protective layer designed to safeguard metal and steel surfaces against fire. It reacts chemically when exposed to heat, expanding multiple times its original thickness to form an insulating barrier known as a char layer.

This char layer acts as a thermal shield, reducing heat transfer to the steel surface beneath. The coating slows down the temperature rise of the metal, effectively delaying structural failure. The key lies in its reactive chemistry — as the paint heats up, its ingredients decompose and expand, creating foam-like insulation that resists flames.

Fire retardant coatings work in several ways:

- Slowing heat transfer to the substrate.

- Providing additional time for safe evacuation and firefighting efforts.

- Preventing rapid structural deformation of steel during a fire.

There are three main types of fire retardant coatings:

- Intumescent Coatings: Expand when heated, creating a thick, carbonaceous insulating layer.

- Fire-Retardant Paints with Chemical Inhibitors: Release flame-suppressing gases to reduce combustion.

- Epoxy-Based Fireproof Coatings: Durable, heavy-duty solutions for harsh industrial conditions.

Each type serves specific environments, but all share the same goal — extending the lifespan of structural steel in fire conditions.

The Science Behind Intumescent Coatings

At the heart of intumescent coatings lies fascinating chemical science. These coatings remain stable under normal temperatures but react dramatically when exposed to fire. Once the surface reaches approximately 200–250°C, the coating activates and begins to expand 50 to 100 times its original thickness.

The reaction forms a carbon foam or char layer that insulates the steel substrate beneath. This barrier drastically slows down heat penetration, keeping the steel’s temperature below its critical failure point.

The formulation typically includes:

- Binders – to adhere the coating to metal surfaces.

- Acid sources (like ammonium polyphosphate) – which catalyze the expansion.

- Carbon sources (such as pentaerythritol) – that form the char layer.

- Blowing agents (like melamine) – which release gases to expand the material.

This multi-step process transforms a thin film into a dense, fire-resistant barrier.

ALTIC FR Coatings employ advanced chemical formulations that ensure consistent performance. Their coatings expand evenly under heat and maintain excellent adhesion, even in extreme industrial environments. This reliability makes ALTIC a preferred choice for architects, engineers, and safety managers seeking long-term, certified fire protection solutions.

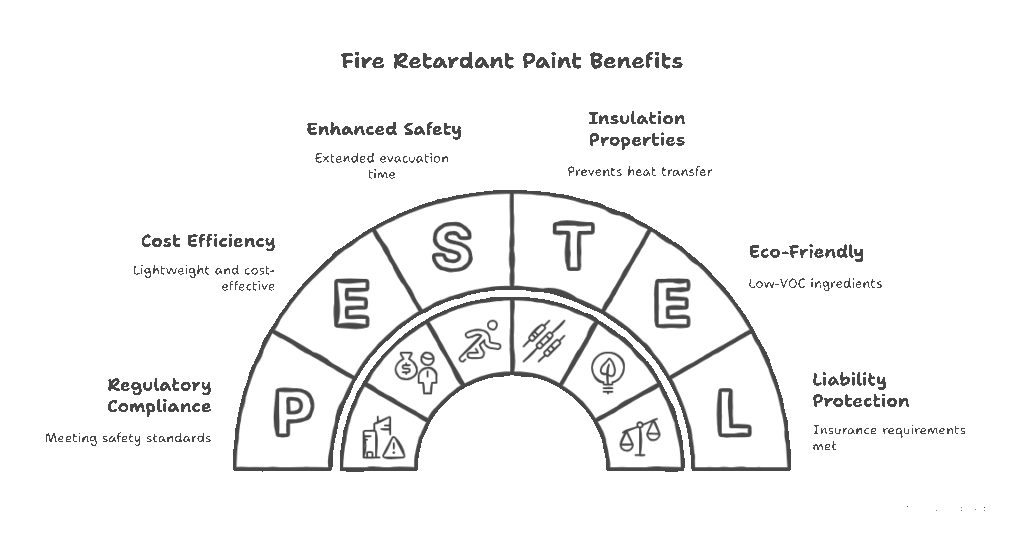

Key Benefits of Fire Retardant Paint for Structural Steel

🧱 Fire Resistance and Structural Integrity

Fire retardant paint significantly increases the fire resistance of steel. By insulating the metal, it prevents it from reaching the critical temperature where it loses strength. This protection ensures that the structure retains its load-bearing capacity, reducing the risk of collapse and enhancing overall fire safety.

🕒 Extended Evacuation and Response Time

In a fire emergency, every second counts. Fireproof coatings for metal provide precious extra minutes for evacuation and firefighting. The coating delays heat transfer, allowing steel structures to maintain integrity longer, reducing injuries and fatalities.

💰 Cost Efficiency and Longevity

Compared to traditional fireproofing materials like cladding or concrete encasement, fire retardant paint offers a lightweight and cost-effective solution. It reduces installation labor, material usage, and long-term maintenance costs while delivering comparable protection levels.

🌿 Aesthetic and Versatile Finish

Unlike bulky fireproof materials, fireproof steel paint offers a smooth, clean, and aesthetic finish. It can be applied in thin layers without altering the architectural appeal of exposed steel beams — perfect for modern designs and visible frameworks.

⚙️ Compliance with Fire Safety Standards

High-quality fire retardant coatings help structures meet essential fire safety codes and certifications such as NFPA, ASTM, and local building regulations. For industrial and commercial facilities, such compliance is not only mandatory but critical for insurance and liability protection.

🧩 Environmental and Sustainable Protection

Modern ALTIC Fire Retardant Paints are formulated with low-VOC and eco-friendly ingredients, contributing to greener construction practices. They protect not just your structure, but also the environment.

Real-World Applications: Where Fire Retardant Paint Matters Most

Fire retardant coatings have become a vital part of modern infrastructure, especially where steel and metal components are exposed to fire risks. Some of the most common applications include:

- High-Rise Buildings: Protecting load-bearing steel frames from collapse.

- Factories and Warehouses: Preventing fire from spreading through steel frameworks.

- Refineries and Power Plants: Shielding critical metal structures from heat and chemical exposure.

- Metro Stations, Airports, and Tunnels: Ensuring safe evacuation during fire emergencies.

- Steel Bridges and Offshore Platforms: Providing protection in environments prone to extreme heat and corrosion.

In all these cases, fire retardant coatings act as an invisible guardian, preserving both structure and safety.

Comparing Fire Retardant Paint with Traditional Fireproofing Methods

| Feature | Fire Retardant Paint | Traditional Methods (Cementitious, Boards) |

| Weight | Lightweight | Heavy |

| Application | Simple spray or brush | Labor-intensive installation |

| Aesthetics | Smooth, modern finish | Bulky and uneven |

| Maintenance | Easy to reapply | Complex repairs required |

| Cost | Moderate and efficient | High installation costs |

| Protection Time | Up to 120 minutes | Varies by method |

Fire retardant paint provides a balance of performance, cost, and appearance that traditional fireproofing systems cannot match. It integrates seamlessly with modern architectural designs, offering safety without compromising design freedom.

Step-by-Step Application Process of Fire Retardant Paint

The application of fire retardant coatings for steel follows a structured process to ensure optimal protection:

- Surface Cleaning and Preparation:

Remove rust, dust, oil, and contaminants to ensure strong adhesion. - Primer Application:

Apply a corrosion-resistant primer compatible with the topcoat. - Fire Retardant Coating Application:

Apply the intumescent coating using a spray gun, roller, or brush in uniform layers. - Topcoat or Sealant:

Finish with a protective topcoat for durability, UV resistance, and visual appeal.

ALTIC Fire Retardant Paints simplify this process with fast-drying formulations, excellent coverage, and compatibility with various metal substrates. Their coatings are designed for both ease of application and long-term performance.

Maintenance and Inspection Guidelines

Even the best fire-resistant coatings require periodic inspection and maintenance to ensure long-term efficiency. Over time, environmental exposure, mechanical impact, or corrosion can reduce coating performance.

Regular maintenance includes:

- Inspecting surfaces for cracks, peeling, or rust.

- Recoating damaged or exposed areas.

- Ensuring consistent thickness through testing.

- Reapplication every few years in harsh industrial conditions.

By maintaining the coating properly, you ensure continuous fire protection for structural steel, extending the life and safety of your assets.

ALTIC Fire Retardant Paint: Setting the Benchmark in Steel Protection

When it comes to industrial fire protection, ALTIC Paints stands as a trusted leader in innovation, performance, and reliability. Their fireproof coatings for metal are engineered to resist extreme temperatures, offering both safety and durability.

Key Features of ALTIC Fire Retardant Paints:

- Exceptional high-temperature resistance.

- Clear or colored options to suit design needs.

- Excellent adhesion and flexibility for steel, aluminum, and other metals.

- Tested and certified to meet international fire safety standards.

ALTIC coatings are used across diverse industries — from infrastructure and energy plants to commercial complexes — helping businesses meet regulatory standards and safeguard their investments.

Choose ALTIC Fire Retardant Paint to protect your structures against unpredictable fire risks.

Invest in safety today — because the right coating doesn’t just protect steel, it protects lives.

Conclusion

In today’s world of complex architecture and industrial growth, fire safety for steel structures is a non-negotiable aspect of responsible construction. Steel may be strong, but without proper fireproofing, its strength can vanish within minutes during a fire.

Fire retardant coatings offer a simple yet powerful solution — they preserve structural integrity, provide valuable evacuation time, and help meet global safety standards. With modern advancements from companies like ALTIC Paints, fire protection is no longer just a precaution — it’s a smart investment in safety, performance, and sustainability.