ALTIC SI Coat System is an advanced, water-based thermal insulation and anti-oxidation coating specifically engineered for high-temperature metal protection. This innovative system offers long-term resistance against heat, oxidation, corrosion, and gaseous chemical reactions on metallic surfaces operating up to 200°C under insulation and 400°C at primer level. Unlike conventional insulation materials that require shutdown and dismantling, ALTIC SI can be applied online, directly on operational equipment—making it the ideal choice for industries seeking uninterrupted production and long-term thermal efficiency.

This three-component coating system includes:

- ALTIC SI Primer – A high-temperature sealer that creates a sealed-porosity layer to prevent oxidation.

- ALTIC SI Basecoat – A thick, insulating layer applied using a texture gun to reduce surface temperature and energy loss.

- ALTIC SI Topcoat – A durable weather-resistant coating providing UV, moisture and environmental protection.

Key Features & Benefits

✔ No Shutdown Required – Applied Online

No need to halt production or equipment operation. The coating is specially formulated for application on hot surfaces, drastically reducing downtime and maintenance costs.

✔ Thermal Insulation & Energy Savings

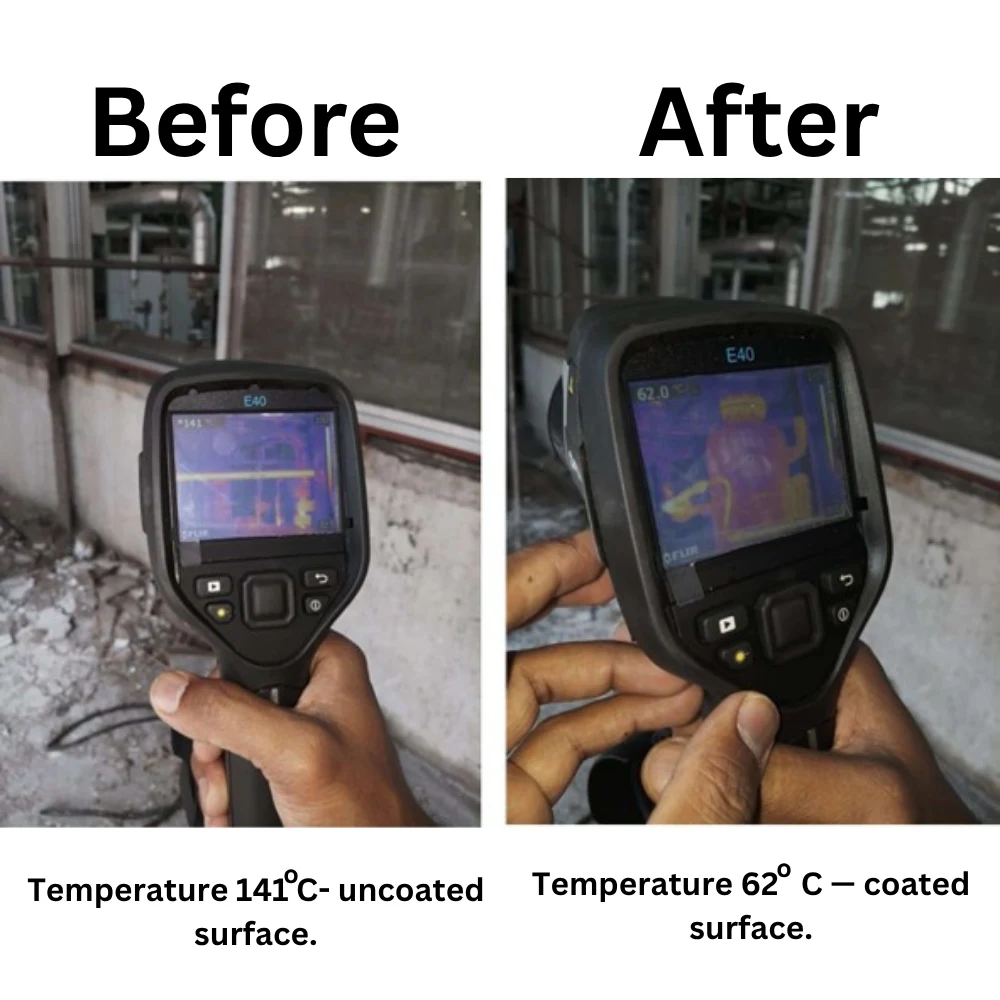

Reduces surface temperature by up to 70–80°C. Example:

- Uncoated Surface: 141°C

- Coated Surface: 62°C

This results in a significant drop in radiation and convection heat losses—over 5000 kcal/hour saved in the sample area test.

✔ Oxidation & Corrosion Protection

Forms a sealed, inorganic protective layer that prevents oxidation, scaling, and metal surface degradation during thermal cycles.

✔ Fireproof & Non-Flammable

An inorganic, water-based formulation that does not catch or spread fire—ensuring enhanced workplace safety.

✔ Eco-Friendly & Sustainable

- Up to 85% recycled content

- Produces 10x less energy during manufacturing compared to traditional insulation

- No glass fiber, mineral wool, or carcinogenic components

- Free from VOCs and hazardous solvents

✔ Weather & Moisture Resistant

Suitable for both indoor and outdoor use. Resists moisture, UV exposure, and environmental wear.

✔ No-Itch Application & Safe for Workers

Unlike glass wool or ceramic fiber insulation, ALTIC SI is non-itchy and safe to handle without health hazards.

Applications

ALTIC SI Coat System is ideal for:

- Hot pipelines (steam lines, process lines)

- Stainless steel, carbon steel, alloy steel, aluminum structures

- Industrial furnaces, boilers, heat exchangers, reactors

- Chimneys, ducts, firewalls, flue gas systems

- Power plants, refineries, petrochemical units

- Oil & gas plants, chemical processing units, OEM machinery

- Replacing glass wool, rock wool or outdated insulation systems where corrosion under insulation (CUI) is a major problem

Technical Specifications

| Parameter | Value |

|---|---|

| Max Use Temperature | 200°C (Basecoat), 400°C (Primer) |

| Composition | Inorganic binders + mixed oxides |

| Liquid Carrier | Water-based |

| Coating Thickness | Primer: 30–40 microns Basecoat: up to 15 mm Topcoat: 80–100 microns |

| Color | Off-white |

| Normal Emittance | 93% |

| Shelf Life | 12 months |

| pH | 10–12 |

| Finish | Nearly water-insoluble after drying; fully water-insoluble after heating |

| Packaging | 10 kg & 20 kg buckets |

Application Procedure

-

Surface Preparation

-

Clean surface of dust, oil, rust, scale or foreign particles.

-

Do not dilute the product.

-

-

Primer Application (ALTIC SI Primer)

-

Stir with a low-speed mechanical stirrer.

-

Apply one coat using a conventional spray gun.

-

Drying time: 2 hours (hot surface) / 4 hours (cold surface)

-

-

Basecoat Application (ALTIC SI Basecoat)

-

Bring equipment to operating temperature if cold.

-

Use a texture gun with 1mm opening.

-

Apply first coat, allow it to dry with operational temperature.

-

Apply second coat.

-

Continue until achieving 3.25 kg/sq.ft wet film thickness (~1.3 kg dry film).

-

-

Topcoat Application (ALTIC SI Topcoat)

-

Apply 2–3 coats using a spray gun.

-

Coverage: 15 sq.ft per liter.

-

Allow 4 hours interval between coats.

-

Advantages Over Conventional Insulation

| ALTIC SI Coat System | Glass Wool / Mineral Wool |

|---|---|

| No shutdown required | Requires shutdown/removal |

| No moisture absorption | Absorbs moisture, loses insulation |

| Anti-corrosive | Causes corrosion under insulation (CUI) |

| Thin profile (15mm) | Bulky thickness (50–100mm) |

| Non-itchy, safe for skin | Itchy and hazardous |

| Long-lasting, no sagging | Degrades with time & vibration |

| Easy maintenance | Needs frequent replacement |

Safety, Storage & Shelf Life

- Store in a cool, dry place. Keep container tightly closed.

- Shelf life: 12 months from manufacturing.

- Water-based, non-toxic and VOC-free.

- Use gloves, mask and eye protection during application.

- After application and curing, coating becomes water-insoluble and highly durable.

Reviews

There are no reviews yet.