Roofs are no longer just structural elements that sit on top of buildings. In the age of rising temperatures, unpredictable monsoons, energy inefficiency, and sustainability demands, roofs have become the first line of defense—and often the most vulnerable. This dramatic shift has pushed industries, homeowners, architects, and facility managers to seek innovative solutions that go far beyond traditional waterproofing paints or thermal insulation sheets.

Among these new-age solutions, one technology stands out as the fastest-growing and most effective: Elastomeric Heat-Resistant & Waterproof Coatings.

These coatings are not merely paints. They’re engineered protective membranes designed to reflect heat, seal micro-cracks, prevent leaks, strengthen roof surfaces, and extend the overall lifespan of a structure. As climate challenges intensify and infrastructure expectations evolve, elastomeric coatings are shaping the future of roof care.

This comprehensive guide breaks down everything you need to know—from science and benefits to applications and future trends.

Why Roof Protection Is Changing Forever

Rising Temperatures

Heatwaves have become longer and more extreme. Roofs in cities often face surface temperatures above 60–70°C during peak summer. Traditional paints degrade quickly, and concrete roofs develop cracks due to thermal expansion.

Unpredictable Rainfall

Monsoons are no longer consistent. Sudden heavy downpours, prolonged humidity, and standing water expose roofs to severe leakage problems.

Energy Efficiency Demands

Cooling costs have skyrocketed. Buildings lose up to 35% of energy through untreated roofs. A heat-resistant roof can reduce indoor temperatures by 5–12°C, significantly lowering electricity bills.

Longevity and Reduced Maintenance

Property owners are demanding durable solutions that reduce long-term repair expenses. Elastomeric coatings offer extended protection—with some formulations lasting 8–12 years depending on climate.

Environmental Requirements

Green building certifications such as IGBC, LEED, and GRIHA emphasize sustainable roofing systems, heat-reflective coatings, and reduced carbon footprint.

The roofing industry is evolving—and elastomeric coatings are at the center of this transformation.

What Exactly Are Elastomeric Roof Coatings?

Elastomeric coatings are high-performance, flexible, acrylic-based, polymer-rich coatings capable of expanding and contracting with roof surfaces. The term “elastomeric” refers to its elasticity—its ability to stretch and return to its original form without cracking.

Key Properties

- High elasticity (300–600% elongation)

- Superior waterproofing

- Thermal insulation & heat reflectivity

- Crack-bridging capability

- UV resistance

- Anti-fungal properties

- Strong adhesion to multiple substrates

Unlike conventional paints, elastomeric coatings act like a protective shield, forming a seamless, durable membrane across the roof.

How Elastomeric Coatings Deliver Heat Resistance

Heat resistance in elastomeric coatings comes from advanced ingredients such as:

A. Solar-Reflective Pigments

Special pigments reflect infrared (IR) radiation that typically heats up roofs. High-quality elastomeric coatings achieve 75–90% solar reflectance, lowering surface temperatures dramatically.

B. Heat-Insulating Microspheres

Hollow microspheres or ceramic beads create an insulating barrier, reducing thermal conductivity. This keeps interiors cooler even when the roof is exposed to continuous sunlight.

C. UV-Resistant Polymers

UV rays degrade normal paints, but elastomeric coatings withstand them for years without chalking, peeling, or fading.

D. Low Thermal Conductivity

The formula slows down heat transfer into the building, making it ideal for homes, warehouses, commercial buildings, and industrial sheds.

The result?

A comfortable indoor environment with lower AC usage—especially during peak summer.

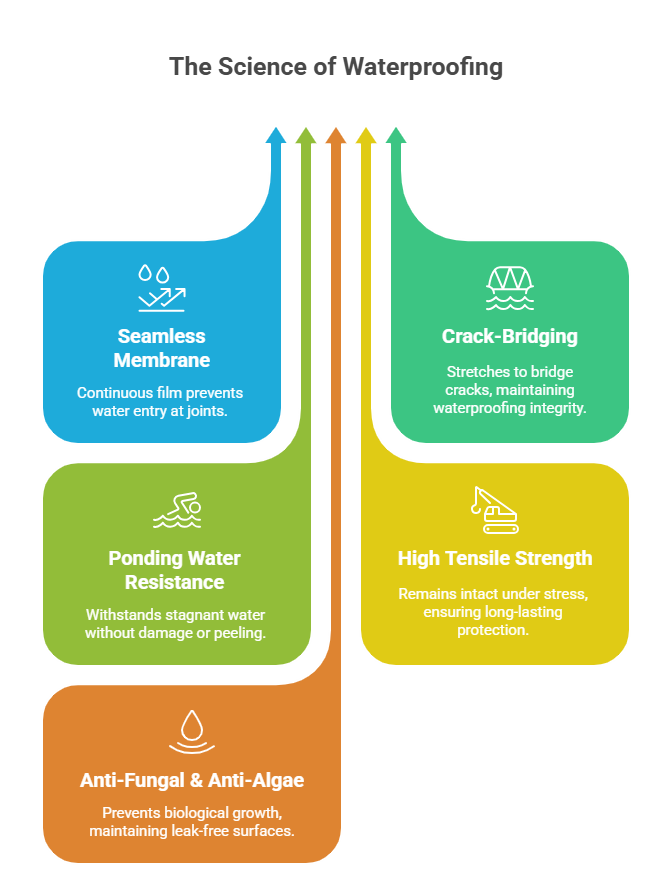

The Waterproofing Power: How Elastomeric Coatings Stop Leaks

Elastomeric coatings are engineered to provide 100% waterproofing protection through a multi-mechanism approach:

1. Seamless Membrane

They form a continuous film with no joints, preventing water from entering common leakage points.

2. Crack-Bridging Capability

Roofs naturally expand and contract. Traditional waterproofing cracks under pressure, while elastomeric coatings stretch and bridge these cracks—even those up to 2–3 mm.

3. Ponding Water Resistance

Some roofs develop depressions where water stagnates. Elastomeric coatings are designed to withstand ponding water without blistering or peeling.

4. High Tensile Strength

This helps the coating remain intact even under foot traffic, equipment movement, or structural vibrations.

5. Anti-Fungal & Anti-Algae Formula

Prevents biological growth, ensuring leak-free surfaces during humid weather.

5. Types of Roofs That Benefit Most from Elastomeric Coatings

Elastomeric coatings are versatile and compatible with:

- Concrete roofs

- Metal roofs (industrial sheds, warehouses)

- Asbestos and fiber cement sheets

- Bitumen-based roofs

- Wooden roofs (after priming)

- Terracotta tiles

- Polyurethane foam roofs

- Old painted surfaces needing refurbishment

This makes them suitable for both old and new structures, residential and industrial applications.

Step-by-Step Application: How Professionals Do It

Roof coating is a science—and following the correct process is essential for long-lasting results.

Step 1: Surface Cleaning

Dust, algae, loose paint, and debris are removed using pressure washing.

Step 2: Crack Filling & Repair

Visible cracks are filled with elastomeric putty or polymer-based fillers.

Step 3: Primer Application

A penetrating primer enhances adhesion and seals pores.

Step 4: First Coat

Applied uniformly using rollers, brushes, or spray equipment.

Step 5: Second Coat (Cross Direction)

Ensures full coverage and thickness.

Step 6: Curing

Coating should dry for 24–48 hours depending on climate conditions.

Recommended Dry Film Thickness (DFT):

1–1.5 mm for best waterproofing performance.

The Biggest Benefits of Elastomeric Heat-Resistant & Waterproof Coatings

1. Reduces Roof Temperature by 15–20°C

This leads to comfortable interiors and lower electricity bills.

2. Extends Roof Life

Protects against structural damage, cracks, and UV degradation.

3. Stops Leaks Permanently

Creates a robust waterproof membrane.

4. Eco-Friendly Solution

Lower AC usage means reduced energy consumption and carbon footprint.

5. Prevents Roof Deterioration

Moisture, heat, and pollution are effectively blocked.

6. Cost-Effective Alternative to Roof Replacement

Instead of re-laying the roof, apply an elastomeric coating for a fraction of the cost.

7. Suitable for All Climates

Be it extreme sun, heavy rain, or temperature fluctuations—these coatings perform reliably.

8. Enhances Building Aesthetics

Available in clean white, grey, and light pastel shades for modern visual appeal.

Real-World Use Cases & Industries Adopting Elastomeric Coatings

1. Residential Houses

For terraces, balconies, and sun-exposed surfaces.

2. Commercial Buildings

Malls, offices, educational institutions, hospitals.

3. Industrial Sheds & Factories

Metal roofs that face extreme sunlight and thermal stress.

4. Storage Warehouses

Maintain lower indoor temperature to protect stored goods.

5. Hotels & Resorts

Improve guest comfort without increasing HVAC costs.

6. Old Buildings Restoration

Revives aged roofs without structural modifications.

7. Solar Panel Structures

Prevents heat buildup under solar installations.

Across these sectors, elastomeric coatings provide measurable improvements in energy savings, maintenance reduction, and structural protection.

Elastomeric Coatings vs Traditional Methods: A Clear Winner

| Feature | Traditional Paints | Bitumen Waterproofing | Elastomeric Coatings |

| Heat Resistance | Low | None | High |

| Waterproofing | Low | Medium | High |

| Flexibility | Low | Low | Very High |

| UV Stability | Low | Poor | Excellent |

| Lifespan | 1–3 years | 2–4 years | 8–12 years |

| Aesthetic Appeal | Good | Poor | Very Good |

| Eco-Friendliness | Medium | Low | High |

| Crack Bridging | None | Low | High |

Conclusion: Elastomeric coatings outperform all other options in durability, performance, and long-term value.

The Science Behind Their Durability

The longevity of elastomeric coatings comes from:

- High polymer content

- Superior adhesion technology

- UV absorbers & stabilizers

- Flexible acrylic resins

- Hydrophobic additives

- Advanced coalescing agents for smooth film formation

Their ability to stretch, compress, and recover makes them ideal for harsh climates and dynamic roof surfaces.

The Future Trends in Elastomeric Roof Coatings

The roofing industry is moving toward smarter, more efficient technologies. Here’s what the future looks like:

1. Cool Roof Technology Integration

Elastomeric cool roof coatings will become mandatory in hot climates to reduce urban heat islands.

2. Nano-Enhanced Formulas

Nanotechnology will enhance UV resistance, durability, and thermal insulation.

3. Self-Cleaning Coatings

Hydrophobic surfaces that repel dust and pollutants automatically.

4. Solar Reflective Index (SRI) Compliance

Governments may introduce minimum SRI requirements for roofing systems.

5. Smart Coatings with Sensors

Emerging technologies could integrate micro-sensors to track moisture levels, temperature, and coating health.

6. Green Building Certification Boost

More builders will shift to elastomeric coatings to meet sustainability guidelines.

The demand for high-performance roof coatings is expected to grow globally by over 15–20% annually, making elastomeric systems the new standard.

Choosing the Right Elastomeric Coating: What to Look For

When evaluating a product, consider:

- Solar Reflective Index (SRI)

- Elongation percentage

- Tensile strength

- DFT recommendation

- UV resistance rating

- Water absorption percentage

- Adhesion test results

- Warranty period

- Manufacturer credibility

Roof protection is an investment—choose wisely.

Conclusion: The Future of Roof Protection Is Already Here

Elastomeric heat-resistant and waterproof coatings represent the most advanced, reliable, and sustainable roofing technology available today. They combine thermal insulation, waterproofing, crack bridging, and UV stability into one powerful solution.

As climate challenges escalate and infrastructure demands rise, these coatings are transforming the way buildings are protected. From homes to industries, modern structures now require roofing systems that do more than just cover—they must defend, insulate, and energize efficiency.