Introduction

With high-rise buildings, business complexes, and industrial structures dominating city skylines in today’s fast expanding world, fire safety compliance has evolved from a legal requirement to a life-saving imperative. In addition to superior architecture, modern building must be resilient to unforeseen risks like fire.

The unsung heroes of passive fire protection in this situation are fire blocks and fire-retardant mortar. These materials are made to keep heat, smoke, and fire from spreading throughout a building. These passive devices function as barriers, providing vital time for evacuation and firefighting operations, in contrast to reactive sprinklers or sirens.

From luxury skyscrapers to Industrial Plants, fire safety compliance has become a cornerstone of modern construction codes. Governments and insurance agencies worldwide are tightening regulations, making fire-rated materials like mortars and blocks mandatory for certification and approval.

In this comprehensive guide, we’ll explore why every modern building needs fire-retardant mortar and fire blocks, the science behind their effectiveness, the latest material innovations, installation best practices, and real-world case studies that highlight their critical importance.

The Growing Need for Passive Fire Protection

Active vs. Passive Fire Protection

Fire safety in construction is typically divided into two categories:

- Active Fire Protection (AFP): Includes alarms, sprinklers, and extinguishers—systems that respond to fire.

- Passive Fire Protection (PFP): Refers to construction materials like fire-rated mortars, boards, and barriers that prevent the spread of fire.

While AFP helps control and extinguish fires, PFP ensures containment, minimizing damage and saving lives.

Why Passive Fire Protection Matters

According to the National Fire Protection Association (NFPA), more than 60% of fire-related fatalities in buildings occur due to smoke inhalation and the rapid spread of flames through unsealed penetrations and poor compartmentalization. Fire-rated mortars and fire blocks seal gaps in walls, floors, and service penetrations, ensuring that a local fire doesn’t become a building-wide catastrophe.

In India, the Bureau of Indian Standards (BIS) and National Building Code (NBC) have made fire compartmentalization mandatory for high-rise structures. Globally, similar standards from the International Building Code (IBC) and European EN 1366 highlight the necessity of passive fire systems in every project.

As urban density increases, fire-rated materials such as fire-retardant mortars and fire blocks are not optional—they’re critical. They form the backbone of construction fire compliance, safeguarding both human life and infrastructure integrity.

Building Codes, Regulations & Insurance Requirements

Fire protection is now a compliance-driven necessity. Most national and international building codes specify mandatory passive fire systems for all large-scale structures.

Key Global Standards

- NFPA (USA): Enforces standards like NFPA 101 Life Safety Code and NFPA 5000 Building Construction and Safety Code, both emphasizing passive protection.

- NBC (India): Mandates the use of fire-rated mortars and sealing blocks in service ducts, risers, and wall openings.

- BS EN & ISO Standards (Europe): BS EN 1366 and ISO 834 govern fire resistance testing for construction materials.

Insurance & Liability

Insurance providers often require proof of fire safety compliance before underwriting large projects. Non-compliance can lead to:

- Claim rejections in case of fire incidents.

- Increased premiums for unsafe or uncertified structures.

- Legal penalties and loss of occupancy certification.

Thus, fire-retardant mortar and fire blocks aren’t merely safety add-ons—they’re essential for regulatory, legal, and insurance compliance.

The Science Behind Fire-Retardant Mortar and Fire Blocks

Fire-Retardant Mortar Composition

A fire-retardant mortar is a cementitious compound composed of:

- Heat-resistant aggregates

- Special additives (such as perlite, vermiculite, or gypsum)

- Binding agents designed to withstand extreme temperatures (up to 1200°C)

When exposed to fire, this mortar forms a hard, non-combustible barrier that insulates against heat transfer and prevents cracks that allow smoke or flames to pass through.

How Fire Blocks Work

Fire blocks are preformed, non-combustible materials used to seal penetrations—like those around cables, conduits, and ducts. They expand under heat, closing off gaps to restrict the movement of flames and toxic gases.

Testing & Certification

Fire-rated materials are rigorously tested under standards such as:

- ASTM E814 / BS (Part 6 and 7): Tests for fire resistance of penetrations.

- EN 1366-3: European testing for service installations.

These tests ensure that the materials provide specific fire resistance ratings (1-hour, 2-hour, 3-hour protection, etc.).

Together, fire-retardant mortars and fire blocks create continuous fire barriers that compartmentalize buildings—key to fire-resistant construction.

Latest Innovations in Fire-Protection Materials

The construction industry is evolving rapidly, and so are fire protection technologies.

Eco-Friendly Fire Mortars

Modern fire mortars now feature low VOC formulations and recyclable content, making them compliant with green building certifications such as LEED and GRIHA.

Lightweight & Modular Fire Blocks

Today’s fire blocks are designed to be lightweight, modular, and reusable, significantly simplifying installation and retrofitting in dense service zones.

Hybrid Fire-Protection Materials

Manufacturers are developing hybrid systems that combine insulative and fire-resistant properties, offering dual protection while minimizing wall thickness.

Smart Integration

Some advanced buildings are integrating AI-based fire monitoring systems that interact with passive systems, ensuring faster response and real-time safety analytics.

Sustainability Link

These innovations are driving the next generation of sustainable fireproofing—aligning safety, energy efficiency, and environmental responsibility in one package.

Integration at the Design and Construction Stages

The key to effective fire safety compliance lies in early integration during the design phase.

Why Early Planning Matters

Retrofitting fire protection after construction is expensive and inefficient. Integrating fire-retardant mortar and fire blocks at the design stage:

- Prevents rework and structural disruption.

- Ensures continuous, tested fire barriers.

- Reduces inspection and approval delays.

Strategic Placement

Critical zones for installing passive fire systems include:

- Wall and floor junctions

- Service risers and duct openings

- Cable trays and pipe penetrations

Collaboration & Technology

Architects, engineers, and fire consultants must collaborate from day one. Using Building Information Modeling (BIM) helps map fire barriers digitally, ensuring accurate installation and code compliance before construction begins.

By embedding fire-resistant materials into the architectural DNA of a structure, professionals can ensure long-term construction safety compliance.

Specification & Maintenance Guidelines

Proper selection and upkeep are crucial for reliable fire-barrier system performance.

Step-by-Step Specification Guide

- Evaluate Fire Rating Requirements: Determine required resistance (e.g., 1-hour, 2-hour) based on structure type.

- Choose Certified Materials: Select products tested to standards like ASTM E814 or EN 1366.

- Hire Qualified Installers: Improper application can compromise the system’s integrity.

- Ensure Compatibility: Match fire mortars and blocks with surrounding materials to avoid cracking or detachment.

- Document Installation: Maintain records for inspection and compliance audits.

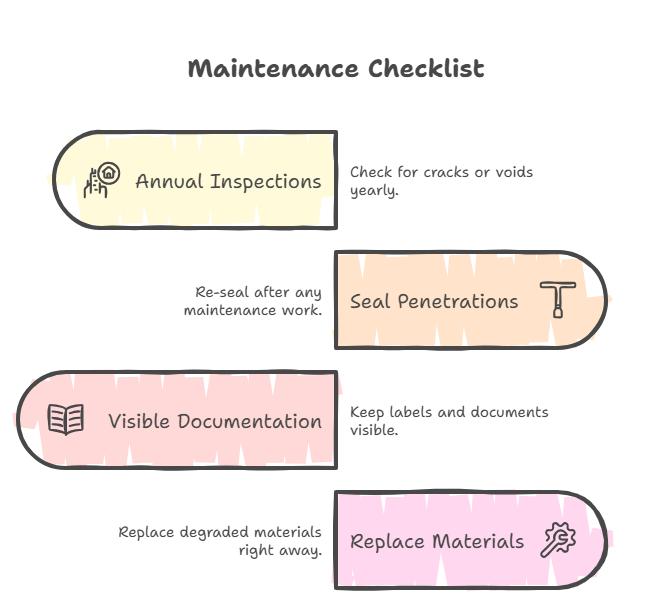

Maintenance Checklist

- Conduct annual inspections for cracks or voids.

- Re-seal any disturbed penetrations after maintenance work.

- Ensure labels and documentation remain visible for auditors.

- Replace degraded materials immediately.

Consistent fire-block maintenance and fire safety inspections ensure systems remain effective throughout the building’s lifespan.

Real-World Case Studies & Lessons Learned

Case Study 1: Successful Fire Containment

A major data center in Singapore installed fire-retardant mortars and modular fire blocks across all cable penetrations. When a minor electrical fire broke out, the system effectively contained the flames to one compartment, preventing server damage and downtime—saving millions.

Case Study 2: The Cost of Neglect

In contrast, a residential tower in Dubai faced a devastating blaze due to unsealed service shafts and non-rated sealants. The fire spread through multiple floors within minutes, highlighting the catastrophic consequences of neglecting passive fire protection.

Lesson Learned

Proper use of fire-barrier systems can be the difference between containment and catastrophe. Compliance isn’t just about codes—it’s about protecting lives, assets, and reputations.

The Future of Fire Safety & Sustainable Construction

The construction landscape is moving toward smart, sustainable, and resilient buildings—and fire-retardant materials are central to that shift.

Emerging Trends

- AI-driven risk detection in passive fire systems.

- Nanotechnology in fire coatings and mortars for superior thermal resistance.

- Prefabricated fire modules for faster and cleaner installations.

Regulatory Evolution

Governments are tightening fire safety norms globally. Future building codes will likely mandate integrated passive systems from the planning phase itself.

Sustainability Connection

Fire-resistant construction supports energy efficiency by improving insulation and longevity, aligning with green building frameworks like LEED, BREEAM, and GRIHA.

ALTIC Paints and similar innovators are leading this evolution—developing advanced passive fire protection solutions that merge safety, durability, and sustainability.

Conclusion

Fire safety isn’t optional—it’s an ethical and professional responsibility. Fire-retardant mortar and fire blocks are indispensable tools in modern passive fire protection, ensuring compliance, saving lives, and preserving assets.

They provide invisible yet powerful barriers that prevent the spread of fire, safeguard occupants, and ensure that buildings meet the highest fire safety compliance standards.

Architects, engineers, and developers must make a commitment to fire-resistant building as cities get higher and denser—not only for regulatory approval but also for sustainability and long-term safety.